Vehicle technology is evolving faster than ever. How can human technicians keep up?

First, collision repair does not require improving the vehicle beyond its original design. When working with Advanced Driver Assistance Systems (ADAS): sensors, cameras, and software, it is the technician’s job to restore the system to its original working condition, not to enhance it. Every year brings new calibration rules, scan requirements, and diagnostic tools.

Shops that fall behind may not feel the impact right away. But over time, they risk losing higher revenue repair work with ADAS and advanced vehicle systems, while being left with only traditional collision repairs.

The good news is that shops can adapt without expensive training programs or major downtime. Here are two practical decisions auto body shops can make.

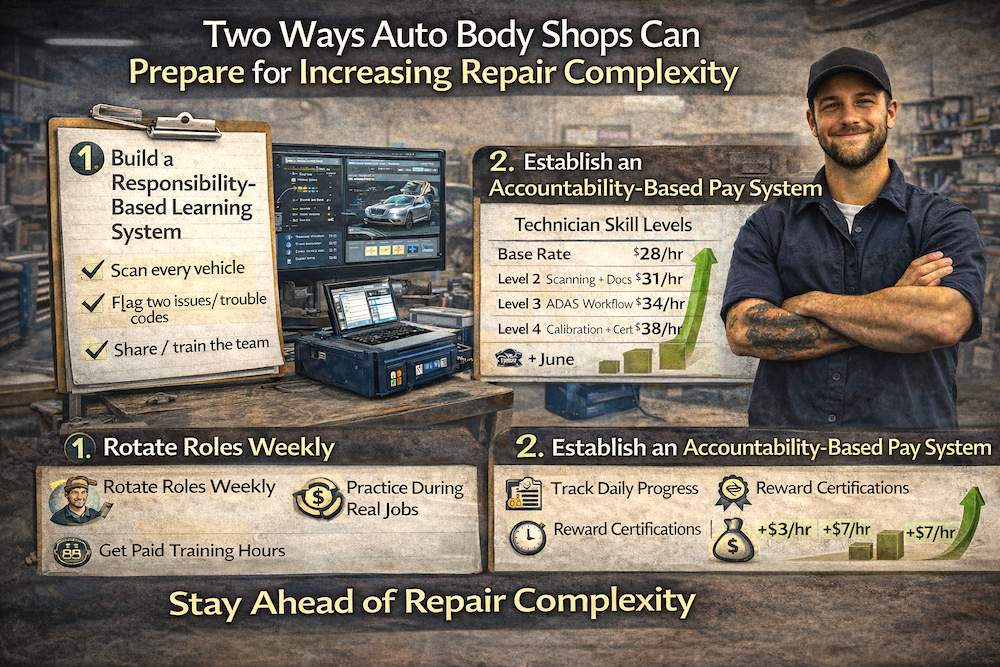

1. Build a Responsibility-Based Learning System

Treat training and learning as if they are part of the job, not optional.

Practice on real repair orders. Each technician needs to participate in the training with no exceptions and no volunteers. Responsibilities rotate so everyone gains experience across different tasks but not limited to:

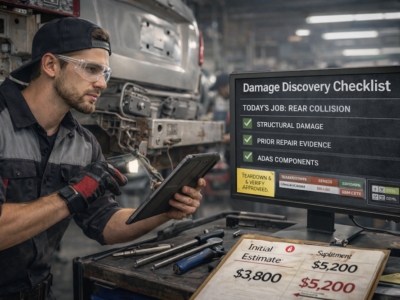

- Scan every vehicle.

- Review the scan report.

- Flag two issues or trouble codes.

- Assign one technician to research them.

- The next morning, the technician explains the findings and repair procedure to the team

Do this every day.

When this training process is scheduled, paid, and tracked, technicians should take it seriously. While the training may slow daily operations at first, the long-term benefits to skill level, work quality, and shop culture outweigh the short-term downside.

2. Build an Accountability-Based Pay System

If the mandatory training is the stick, then the pay ladder is the carrot.

It is important to treat training as more than just part of daily work. One effective way to do this is to link pay directly to a technician’s skill level, as approved by the shop owner. This creates clear personal incentives to learn and improve.

Create clear levels of hourly pay:

- Base rate

- Level 2: Technician can perform basic scans and documentation.

- Level 3: Technician understands the general ADAS workflow.

- Level 4: Technician can perform calibrations and holds additional certifications.

Add simple individual recognition:

- Monthly titles such as Scan Captain or Calibration Lead.

- $50–$150 bonuses for earning new certifications, learning and sharing new technology, or making meaningful improvements in repair processes.

Track overall performance using clear metrics:

- % pre-scanned completed.

- % post-scanned completed.

- Calibration documents completed.

Update these numbers daily and post them where everyone in the shop can see.

Auto body shops that treat learning as a system and pay for skill, not time, will stay profitable as collision repair grows more complex.